Saturday, November 9, 2024

10x12 shed plans: how to build your own for less

Hey there, DIY enthusiasts! So, you're thinking about building a 10x12 shed, eh? You're in the right place! Building your own shed is an awesome way to get a super useful space without breaking the bank. Plus, there's something really satisfying about seeing your hard work come to life, brick by brick (or should I say, board by board?).

Let's dive in and break down this project into manageable steps. I'm not going to overwhelm you with super technical jargon â€" think of this as a friendly guide, like having a buddy alongside you on this journey.

1. Laying the Foundation:

The foundation is like the bedrock of your shed. You want it to be strong and level to avoid any wobbly walls. There are a few options here:

Concrete Slab: This is the most robust option and perfect if you're planning on a heavy-duty shed. It's a bit more work and needs some know-how, but trust me, it's worth it for long-term stability.

Concrete Pier Foundation: This is a great middle ground. You'll create individual concrete piers at strategic locations and then rest your floor joists on top. It's easier to work with than a slab and still offers good support.

Pressure-Treated Wood Piers: This is the simplest and most budget-friendly option. You'll use pressure-treated wood to create the piers and then rest your floor joists on top. Just make sure you're using the right grade of lumber for durability.

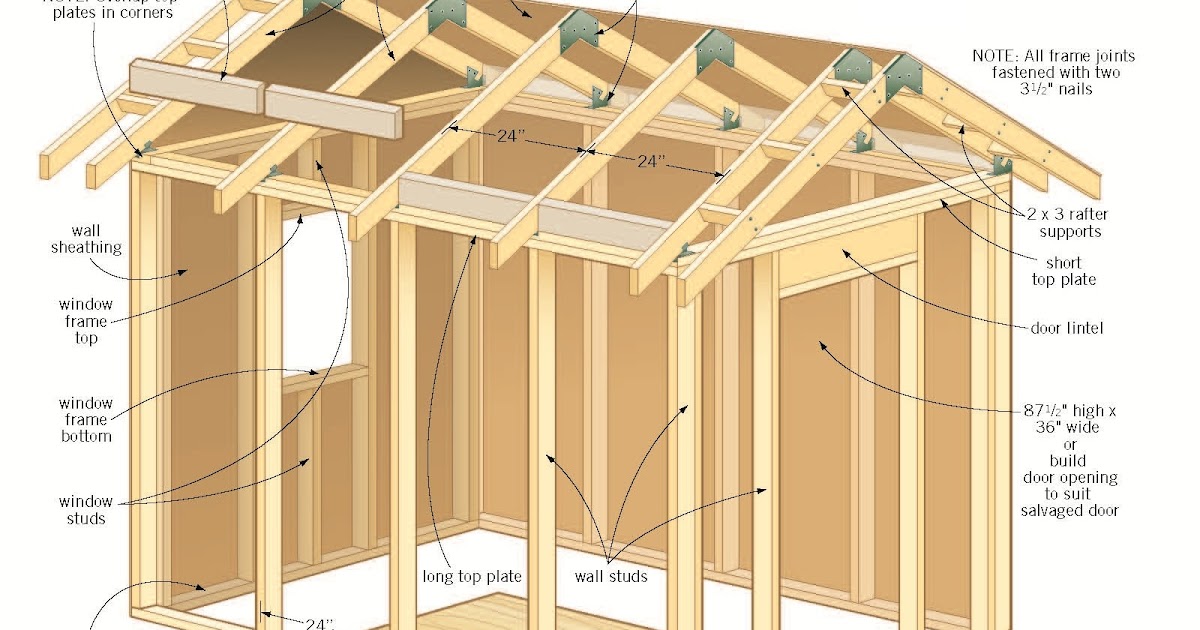

2. Framing Up Your Walls:

Now, it's time to start building your walls. Get your lumber ready (we're talking 2x4s and 2x6s, usually!), and don't forget your stud finder!

Cutting and Assembling Walls: You'll need to cut your lumber to the right lengths for your walls. Then, you'll assemble them using nails or screws, creating sturdy frames. It's a good idea to double-check your measurements and make sure everything's square and level.

Sheathing the Walls: This is like giving your walls a protective layer. You'll attach plywood or OSB sheathing to the wall frames, giving them additional strength and creating a surface for your siding to attach to.

3. The Floor: A Solid Base

Time to build that floor! It's a pretty straightforward process, but don't skip any steps.

Laying the Floor Joists: These are the beams that will run across your shed, providing support for your floorboards. They're usually spaced 16 inches apart.

Subfloor: You'll lay down plywood or OSB boards on top of the joists, creating a sturdy subfloor that's ready for your finished floor.

Finishing Touches: If you're planning on having a finished floor, now's the time to add it! You can go with wood flooring, concrete, or even tiles â€" the choice is yours!

4. The Roof: Keeping Things Dry

A good roof is essential for keeping your shed protected from the elements. This is where things can get a bit more involved, but don't worry, it's still manageable.

Rafters and Truss System: This is the backbone of your roof. You'll be creating a system of rafters or trusses that will support your roof sheathing and shingles.

Roof Sheathing: This is the layer that goes on top of the rafters or trusses and provides a solid base for your roofing material.

Shingles or Roofing Material: There are lots of options here â€" asphalt shingles, metal roofing, or even wood shakes. Choose what fits your style and budget!

5. Siding and Trim: Finishing Touches

We're nearing the end! Now, it's time to give your shed that final, polished look.

Siding: This is the visible outer layer of your shed. You can go with vinyl siding, wood siding, or even a more rustic look with rough-sawn lumber.

Trim: This is the finishing touch that adds a touch of style to your shed. You can use trim around the doors, windows, and edges to create a clean and polished look.

6. Doors and Windows: Let the Light In

Now, let's add those doors and windows for easy access and natural light!

Door Installation: This is a two-person job. You'll need to measure carefully and install the door frame and the door itself.

Window Installation: Just like doors, windows need precise measurements for a seamless installation.

7. Finishing Up:

You're almost there! Now, let's wrap up the final details.

Painting or Staining: This is where you can truly personalize your shed! Choose your favorite color or stain to add a touch of character.

Interior Finishing: Decide how you want to finish the inside of your shed. You might want to add insulation for warmth and soundproofing, or maybe you'll just leave it as a clean, open space.

Tips and Tricks:

Plan and Measure: Before you even start, take your time to plan and measure everything carefully. It's much easier to make changes on paper than on a half-built shed!

Don't Rush: Building a shed takes time. Don't try to rush the process; enjoy it!

Safety First: Always prioritize safety. Wear safety glasses, gloves, and sturdy shoes.

Ask for Help: Don't be afraid to ask for help if you need it. Having an extra pair of hands can make a big difference, especially with heavier tasks.

Celebrate Your Success: Once you're done, take a moment to admire your hard work! You've just built your very own 10x12 shed!

Cost Considerations:

Building your own shed is a great way to save money, but it's important to budget realistically. The cost of materials can vary depending on where you live and the quality of the materials you choose. Here's a breakdown of approximate costs (keep in mind, these are rough estimates):

Lumber: $500-1000

Foundation materials (concrete, piers, etc.): $200-500

Roof sheathing and shingles: $200-400

Siding: $200-400

Doors and windows: $200-500

Hardware (screws, nails, etc.): $100-200

Overall, you could build a 10x12 shed for around $1500-3000, depending on your choices.

Remember: Building a shed is a journey, not a race. Take your time, enjoy the process, and don't be afraid to ask for help. You'll be amazed at what you can accomplish with a little planning, hard work, and a positive attitude. Now go forth and build!